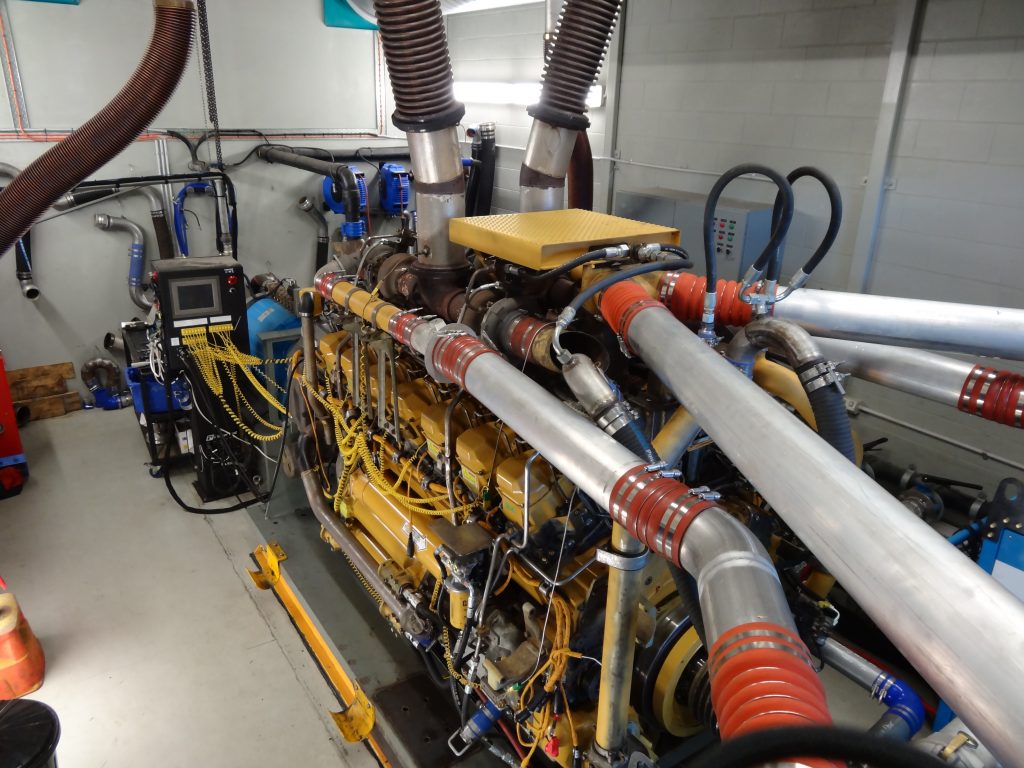

Dynamometer Testing

H-E Parts provides world class industrial diesel engine re-manufacturing services to the mining, stationary power, and oil and gas industries. Our dedication to quality and precision ensures that every one of our engine re-builds runs like new. To ensure StaTerra Power™ diesel engines afford our customers the lowest total cost of ownership, all engine rebuilds and

service exchange units undergo extensive commissioning, testing and analysis. This ensures our customers not only receive a significant cost saving over a new engine, but also a high quality product that can be relied upon. All testing is conducted by trade qualified and highly trained technicians who ensure consistency with work flows to meet client demand.

H-E Parts engine dynamometers are capable of testing, diagnosing and reporting on the following parameters:

- Checking individual cylinder temperatures on all engines to ensure optimum performance is achieved

- Determine correct levels of fuel burn are measured to meet approved performance specifications and that these are achieved for each engine tested

- Ensure all engines are running at optimum coolant temperature and correct oil pressures are achieved

H-E Parts engine dynamometer testing offers our customers the following benefits:

- Efficiently troubleshoot low horsepower, insufficient torque, boost issues, leaks and identification of any other engine issues

requiring attention whilst under test or simulated machine load - Any required repairs or adjustments can then be carried out so a ‘before and after’ test report can then be compiled and sent to our customer upon completion

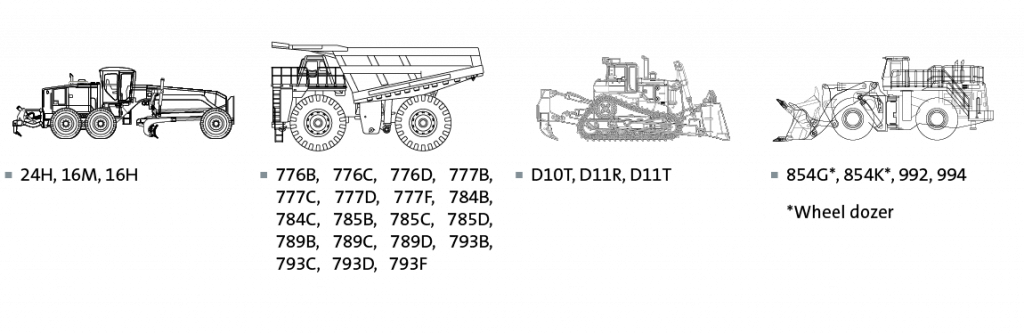

Dynamometer Test Coverage

H-E Parts’ ability to conduct testing in-house means service delivery and engine rebuild time frames are reduced with no reliance on third-party suppliers for testing. H-E Parts has the capability to dyno test engines up to 4200 HP and are predominantly used for Caterpillar C27, C32, C175 and the full range of 3500 series engines.

Powertrain hydraulic test bench (AU Only currently)

H-E Parts powertrain testing utilizes the latest shift analyzer along with software and test harnesses, that align to strict quality and proprietary test procedures. Testing is available on a wide range of late model components, with a full suite of test reports available that document all final results that meet with OEM specifications for each component.

H-E Parts ability to conduct testing in-house means service delivery and component rebuild time frames are reduced with no reliance on third party suppliers for component testing.