ENGINEERED SOLUTIONS

At H-E Parts we provide tailored, specialized in-house engineering, drafting and project management services to the mining, quarrying and aggregates industries globally. With vast project experience in global markets, we are positioned to provide engineered solutions to service all types of mineral processing plants, materials handling and associated equipment. Our services and solutions offer customers the opportunity to benefit from our global transferable best practices. Our dedicated engineering and drafting teams play a pivotal role in providing value to the client, as expertise extends from industry professionals to mechanical engineers, to QA/QC specialists.

Added Value Through Innovation

Our added value is achieved by providing fit-for-purpose design, innovation through engineering and quality through service performance. We have been reducing the risks associated with the installation, maintenance and servicing of mining, quarrying and processing equipment since our inception, and this can be demonstrated via our stringent liner development program;

Customer target goals are defined.

- Specific site conditions/application is assessed and crusher parameters, feed data, current liner life etc. identified.

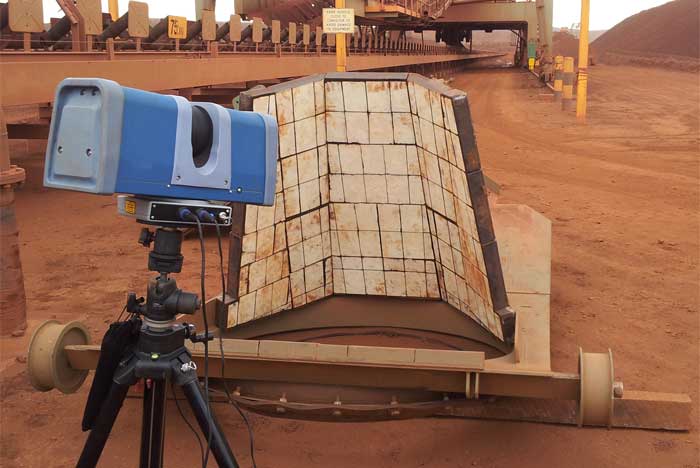

- 3D laser scanning on new and worn liners is conducted, with extracted data used with ChamberVision™ and CrusherVision™ software.

- ChamberVision simulation is conduced to predict wear on proposed new design and allow accurate benchmarking and performance estimates.

- CrusherVision™ simulation is conducted to predict throughput, power draw, crushed product distribution, scenario testing to estimate the effects of changing machine parameters such as speed and eccentric throw, and design-stage analysis tools to prevent issues such as chamber packing. Combining the outputs of CrusherVision™ and ChamberVision™ allows changes in performance to be predicted as liners wear.

This results in first set liners performing as designed, expected and required.